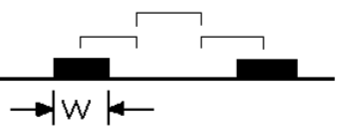

لضمان جودة توجيه الإشارات ومنع التداخل أثناء تصميم لوحة الدوائر المطبوعة، نحافظ على مسافة بين مسارات الإشارة تساوي ثلاثة أضعاف عرض الخط. كما هو موضح في الشكل 1، تشير هذه المسافة إلى المسافة بين مراكز المسارات. ولأن عرض الخط يُعبر عنه باللغة الإنجليزية بكلمة "width"، يُشار إلى هذه القاعدة غالبًا بمبدأ 3W. عندما تكون المسافة بين مراكز المسارات ثلاثة أضعاف عرض الخط على الأقل، يُضمن خلو 70% من المجالات الكهربائية بين الخطوط من التداخل. أما إذا كان المطلوب خلو 98% من المجالات الكهربائية بين الخطوط من التداخل، فيمكن استخدام قاعدة 10W.

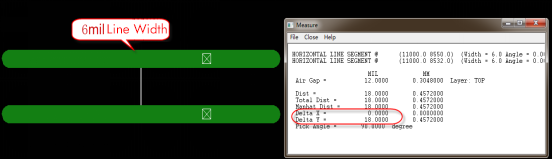

مبدأ 3W هو مبدأ تصميم لوحات الدوائر المطبوعة (PCB) يمكن للمصممين اتباعه دون الحاجة إلى تقنيات تصميم إضافية. مع ذلك، يستهلك هذا النهج مساحة كبيرة وقد يُصعّب عملية التوجيه. تتمثل نقطة البداية الأساسية لمبدأ 3W في تقليل التداخل بين المسارات. يمكن التعبير عن هذا المبدأ كما يلي: يجب أن تكون المسافة بين المسارات (المسافة بين مراكز المسارات) ثلاثة أضعاف عرض المسار الواحد. أو بدلاً من ذلك، يجب أن تكون المسافة بين مسارين أكبر من ضعف عرض المسار الواحد. على سبيل المثال، إذا كان عرض خط الساعة 6 مل، فلا يمكن توجيه المسارات الأخرى إلا على بُعد 2 × 6 مل من هذا المسار، أو يجب أن تكون المسافة بين حواف المسارات أكبر من 12 مل. يُمكن تطبيق مبدأ 3W بسهولة في تصميم لوحات الدوائر المطبوعة من خلال ضمان أن تكون المسافة بين مراكز المسارات ثلاثة أضعاف عرض المسار. على سبيل المثال، إذا كان عرض المسار 6 مل، فيمكن في برنامج Allegro ضبط قاعدة المسافة بين الخطوط على 12 مل لتحقيق مبدأ 3W. يتم حساب المسافة في البرنامج بناءً على المسافة من الحافة إلى الحافة، كما هو موضح في الشكل 2.

مبدأ 3W هو مبدأ تصميم لوحات الدوائر المطبوعة (PCB) يمكن للمصممين اتباعه دون الحاجة إلى تقنيات تصميم إضافية. مع ذلك، يستهلك هذا النهج مساحة كبيرة وقد يُصعّب عملية التوجيه. تتمثل نقطة البداية الأساسية لمبدأ 3W في تقليل التداخل بين المسارات. يمكن التعبير عن هذا المبدأ كما يلي: يجب أن تكون المسافة بين المسارات (المسافة بين مراكز المسارات) ثلاثة أضعاف عرض المسار الواحد. أو بدلاً من ذلك، يجب أن تكون المسافة بين مسارين أكبر من ضعف عرض المسار الواحد. على سبيل المثال، إذا كان عرض خط الساعة 6 مل، فلا يمكن توجيه المسارات الأخرى إلا على بُعد 2 × 6 مل من هذا المسار، أو يجب أن تكون المسافة بين حواف المسارات أكبر من 12 مل. يُمكن تطبيق مبدأ 3W بسهولة في تصميم لوحات الدوائر المطبوعة من خلال ضمان أن تكون المسافة بين مراكز المسارات ثلاثة أضعاف عرض المسار. على سبيل المثال، إذا كان عرض المسار 6 مل، فيمكن في برنامج Allegro ضبط قاعدة المسافة بين الخطوط على 12 مل لتحقيق مبدأ 3W. يتم حساب المسافة في البرنامج بناءً على المسافة من الحافة إلى الحافة، كما هو موضح في الشكل 2.

Xml سياسة الخصوصية المدونة خريطة الموقع

حقوق النشر

@ شركة مايكرو ماجيك كل الحقوق محفوظة.

دعم الشبكة

دعم الشبكة